Have you ever wondered why your wash quality seems better on some days than others, even when seemingly nothing has changed? One answer could be to do with how your laundry chemicals are dispensed into the wash wheel and how seasonal changes can have a major impact.

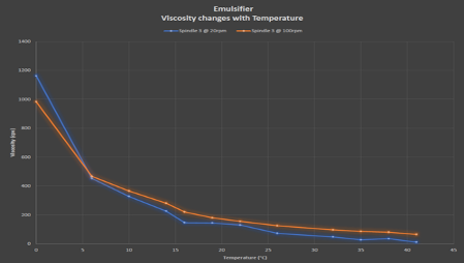

The laundry industry plays a vital role in maintaining hygiene and cleanliness in our daily lives, and the importance of accurate chemical dosage has become increasingly apparent as the industry evolves. Flowmeters have emerged as a critical component in ensuring precise chemical dosing, especially in light of viscosity fluctuations caused by seasonal changes. These variations can occur daily, as per the table below, some minor but others more dramatic.

Australian laundries operate in diverse environments, where temperature and humidity variations occur naturally throughout the year. These seasonal shifts can significantly impact the viscosity of all chemicals used in the laundering process. Traditional volumetric pump calibrations cannot adjust to these fluctuations without daily calibrations, which can lead to inconsistent results. This can compromise the effectiveness of the laundering process and potentially waste valuable resources through increased rewash, energy consumption and labour costs, and give your competitors an advantage.

Flowmeters offer a ready-made solution to this challenge. By measuring the flow rate of chemicals with exceptional accuracy on every injection, flowmeters, when paired with a monitoring platform, enable laundries to confirm dosages in real-time and account for changes in viscosity, line restriction, line blockages or pump failures. This level of precision guarantees that the programmed amount of chemical is received in every load, or you will be alerted in real time if it is not. Additionally, accurate chemical dosing enhances the quality of laundered items, prolongs the lifespan of linen and equipment, and reduces the environmental impact of the laundering process, ensuring you get the lowest possible cost of clean.

Key benefits of flowmeters in the laundry industry include:

- Consistency: Flowmeters ensure that the same amount of chemicals is dispensed regardless of viscosity variations, resulting in consistent cleaning performance and superior results. They also alert you to mechanical failures or blockages, ensuring every load receives the correct dose, which is especially critical when chemically disinfecting.

- Environmental Responsibility: Correct chemical dosing will help reduce rewash, which in turn reduces water, energy, and labour costs, contributing to a more sustainable laundry operation and lower carbon footprint.

- Linen and Equipment Longevity: Accurate dosing prevents the buildup of residue on linen and within machines, reducing replacement linen costs and maintenance requirements by extending the lifespan of both.

- Adaptability: Flowmeters can be easily integrated into existing laundry systems, offering a seamless solution to address external fluctuations.

Incorporating flowmeters into the laundry process demonstrates a commitment to innovation and efficiency. As the laundry industry continues to evolve, it is imperative to adopt technologies that enhance both operational effectiveness and environmental responsibility. Flowmeters stand as a testament to this philosophy, providing laundries with the tools needed to excel in a dynamic and competitive market.

For more information on how your laundry can benefit from using flowmeters call 1300 529 243 (1300 JAYCHEM).

Author: Brad Carruthers, National Technical Manager